Parque de la Cantera de Tangshan

Parc de la Pedrera de Tangshan

Tangshan Quarry Park

PROJECT STATEMENT

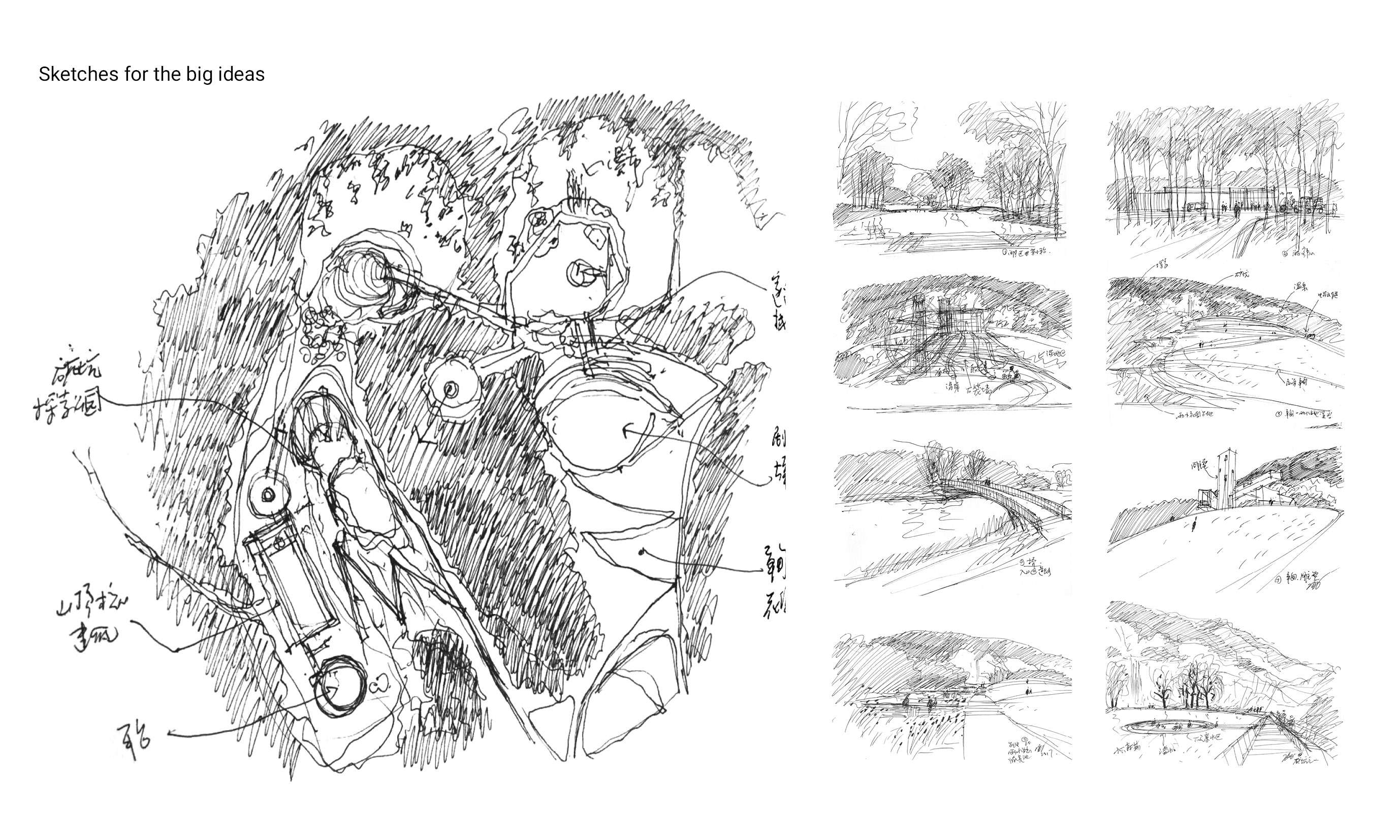

The Tangshan Quarry Park is a project to remediate an abandoned quarry into a biodiversity environment, in the meantime rejuvenate it into a dynamic public space. Facing the given condition of four large quarry craters and severely damaged ecosystem around the quarry, our design response is not only for environmental enhancement, but to create a public education opportunity to increase attention from general public to come across both current and future environmental issues. It is to transform the industrial relic to a territory where people could go deep into, experience the damaged nature with its healing process. The experimental procedure is ever-changing and open ended. It offers exploration and investigation opportunity between time and eternity that binding human beings and the globe together.

PROJECT NARRATIVE

Background

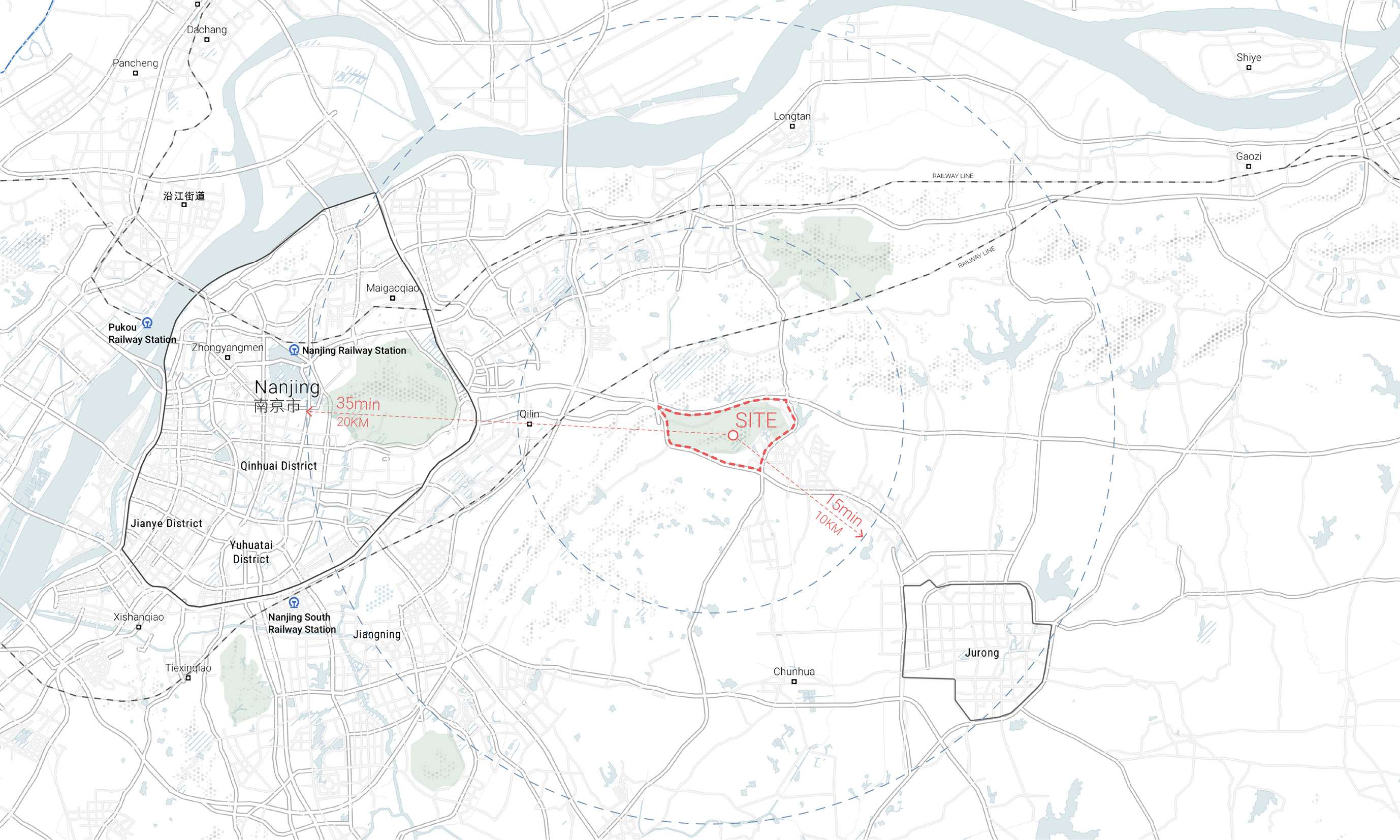

The project is located 30 km from the center of Nanjing City and on the southside of the Tangshan mountain. The quarry formerly known as the Longquan Quarry was the largest limestone mine in the region. It was in operation from 1990 to 2004. Fifteen years of mining left 4 gigantic craters in the southside of the Tangshan mountain. Since 2017, the local government has been collaborating with a team of landscape architects, mountain maintenance engineers and soil ecologists to rejuvenate the abandoned quarry and vicinity area. To restore the damaged ecosystem has been one of the main goals and approaches of this effort.

Issues of the site

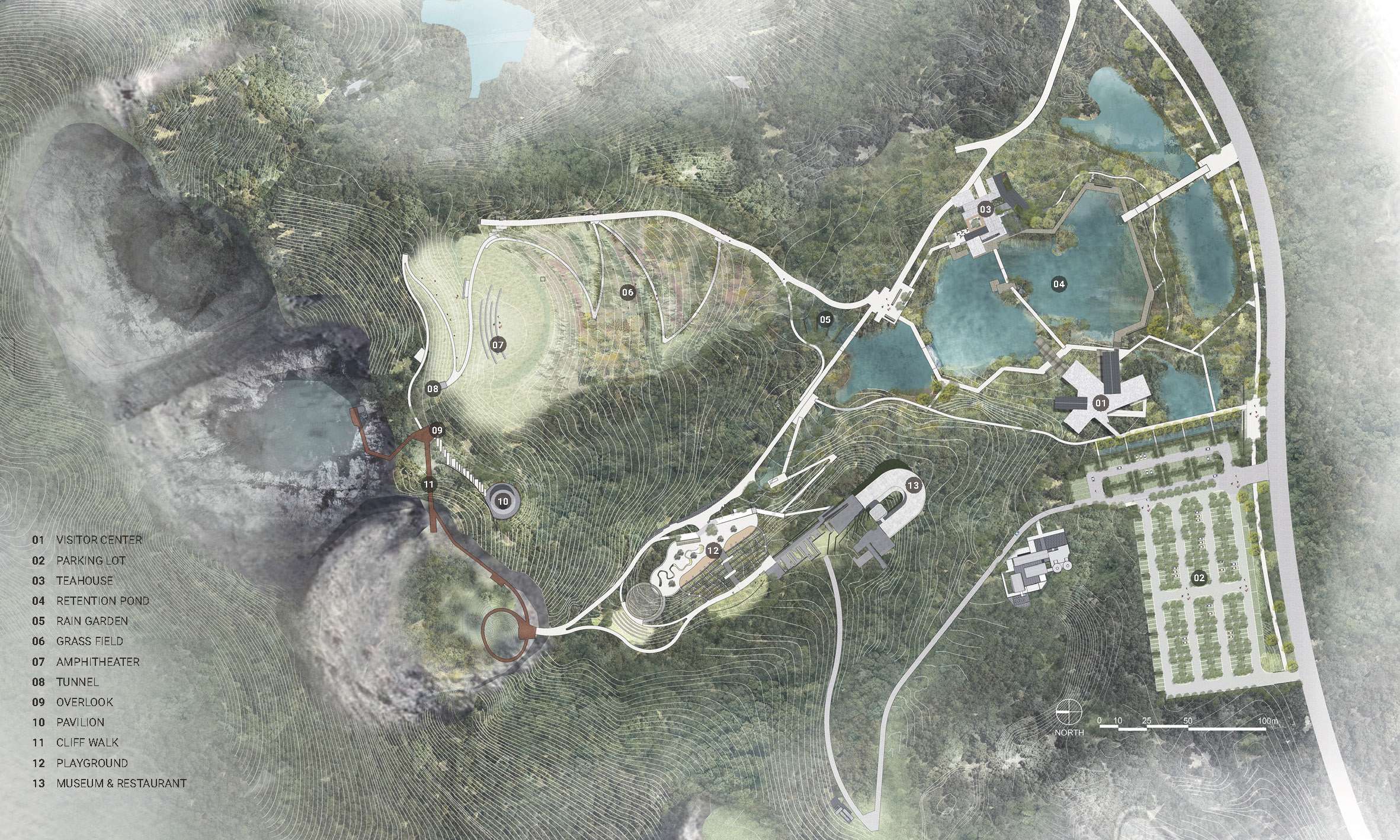

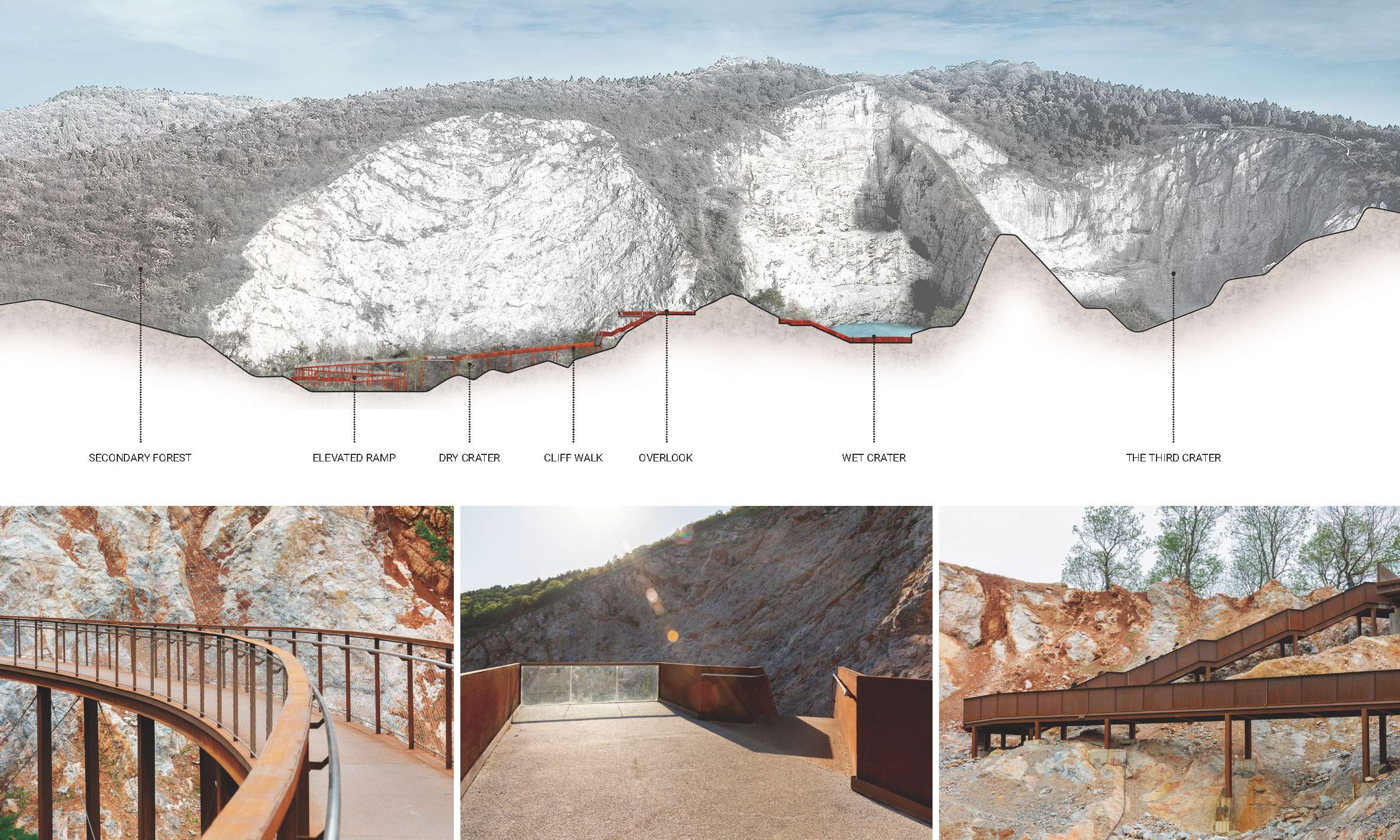

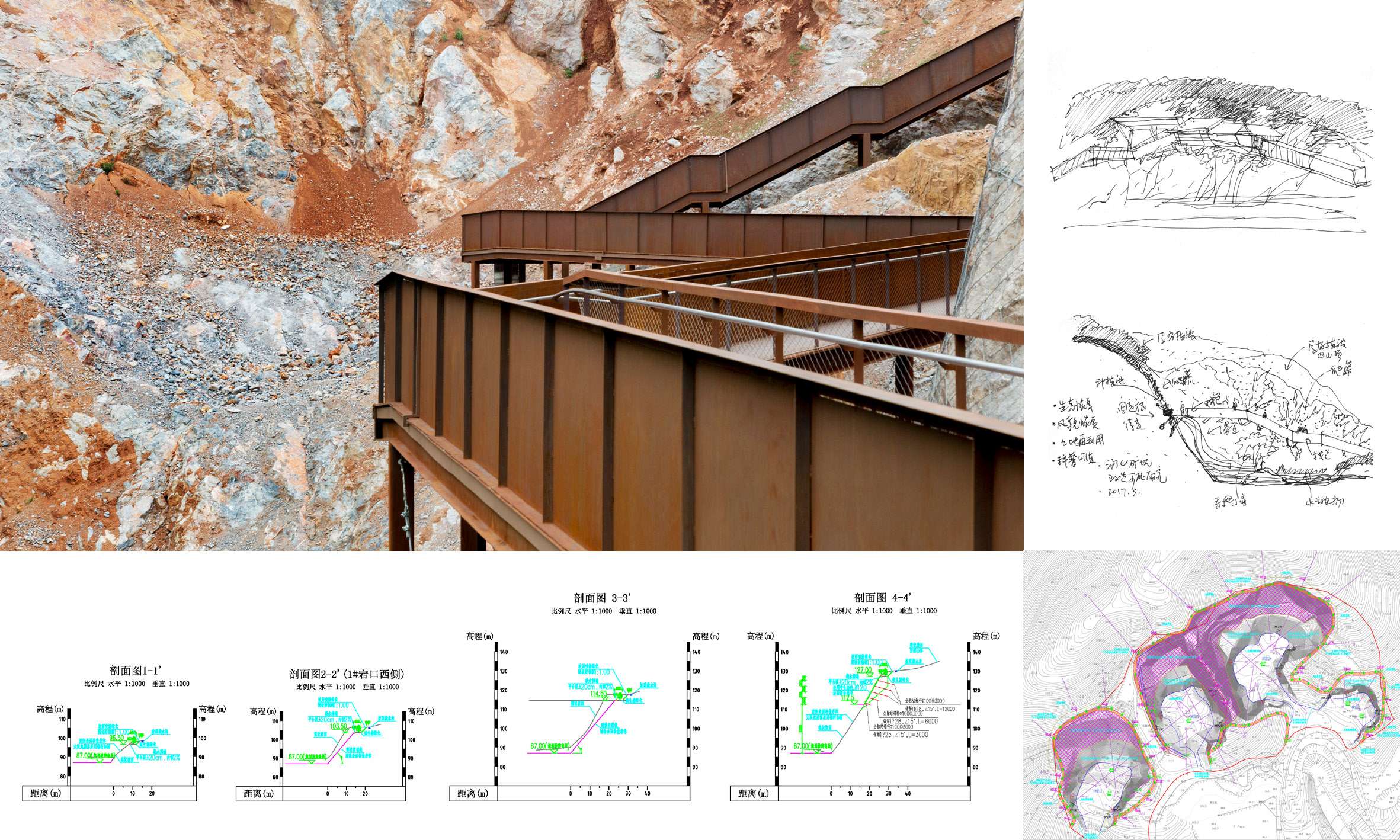

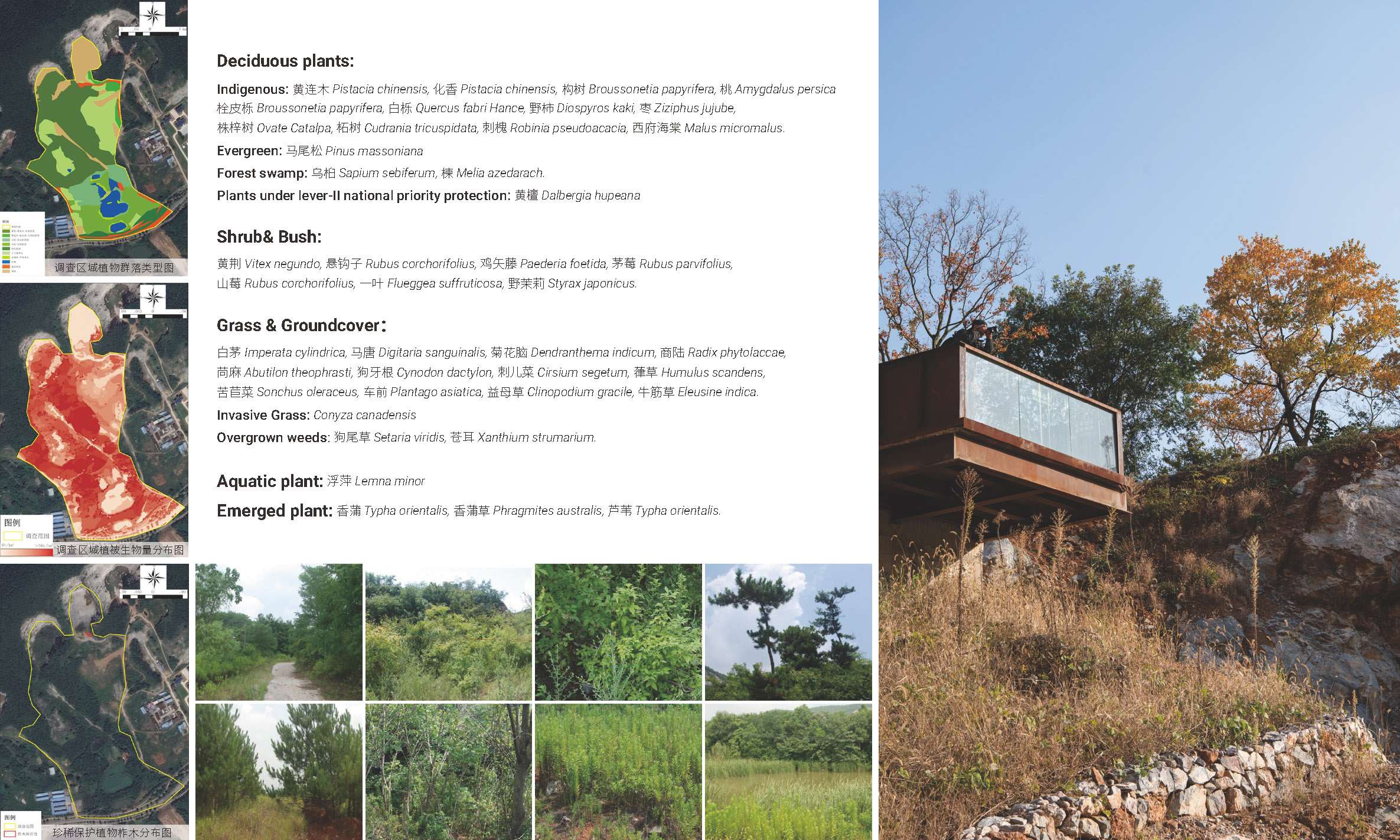

The project covers an area of approximately 40 hectares. The elevation changes on the site vary from 50 to 250 meters. From west to east, the dimensions (Length x Width x Height)of the four craters are respectively: 210 x 180 x 59 meters (elevations from 141.2 to 82.1), 168 x 120 x 87 meters (elevations from 169.4 to 82.01), 177 x 126 x 100 meters (elevation from 198.7 to 98.4), and 167 x 189 x 103 meters (elevation from 197.05 to 93.84). Based on the survey, some rock walls were in the danger of falling and collapsing. The ecological condition of the mountain body outside of the 4 craters and above 100 meters elevation was considered good. This area provided relatively better habitat of most of local plants and animals. The ecological value and sensitivity were at high level. For the area below the elevation of 100 meters, the terrain was gentle. In this area, the human activities were heavy, the ecological value and sensitivity were at low level. The prolonged industrial activities on the site had polluted the water and soil severely. The level of the heavy metal found in the ground water was high. The soil was heavily compacted and mixed with rocks and muck, which offered very poor condition for plant’s growth. The mining activity also damaged the biodiversity of the area.

Solutions

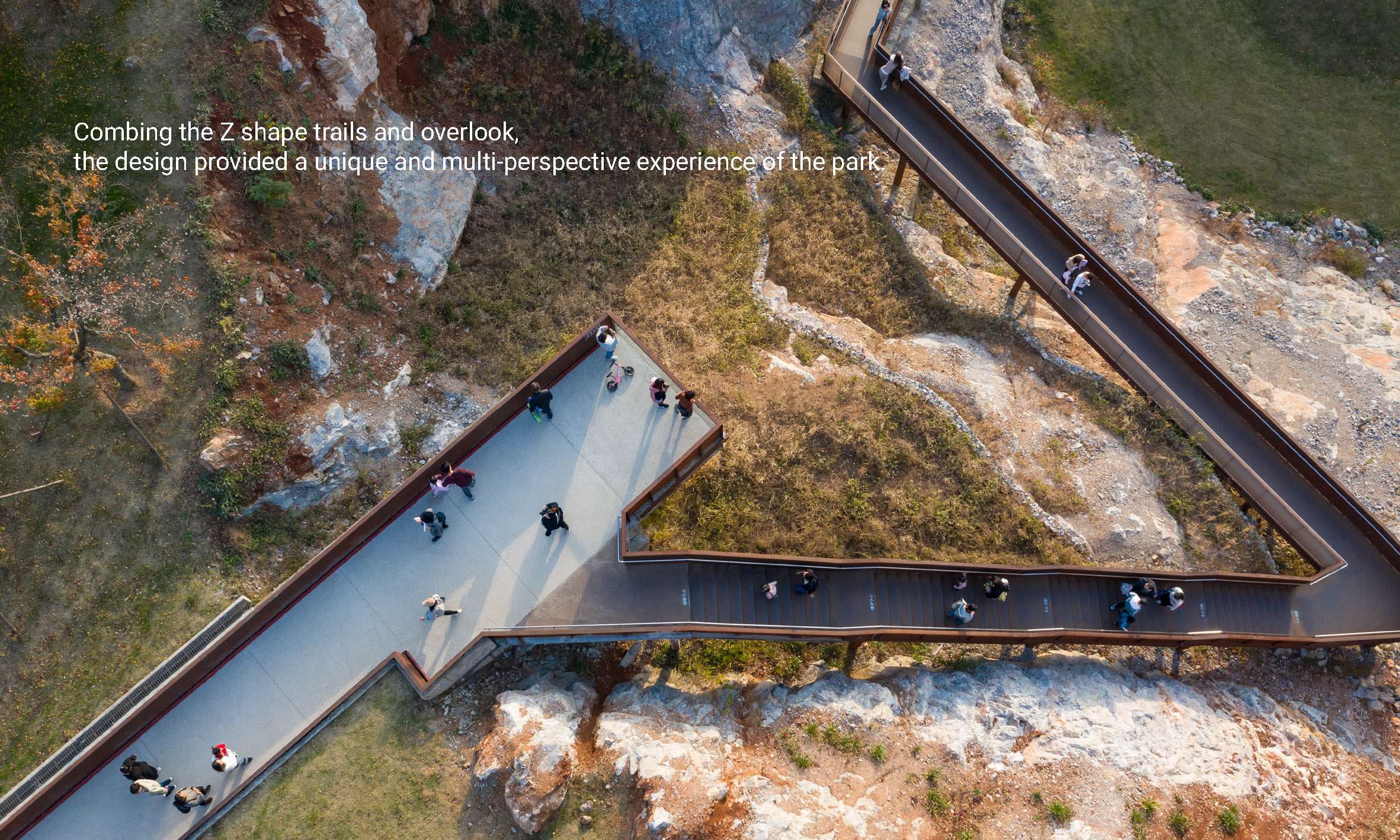

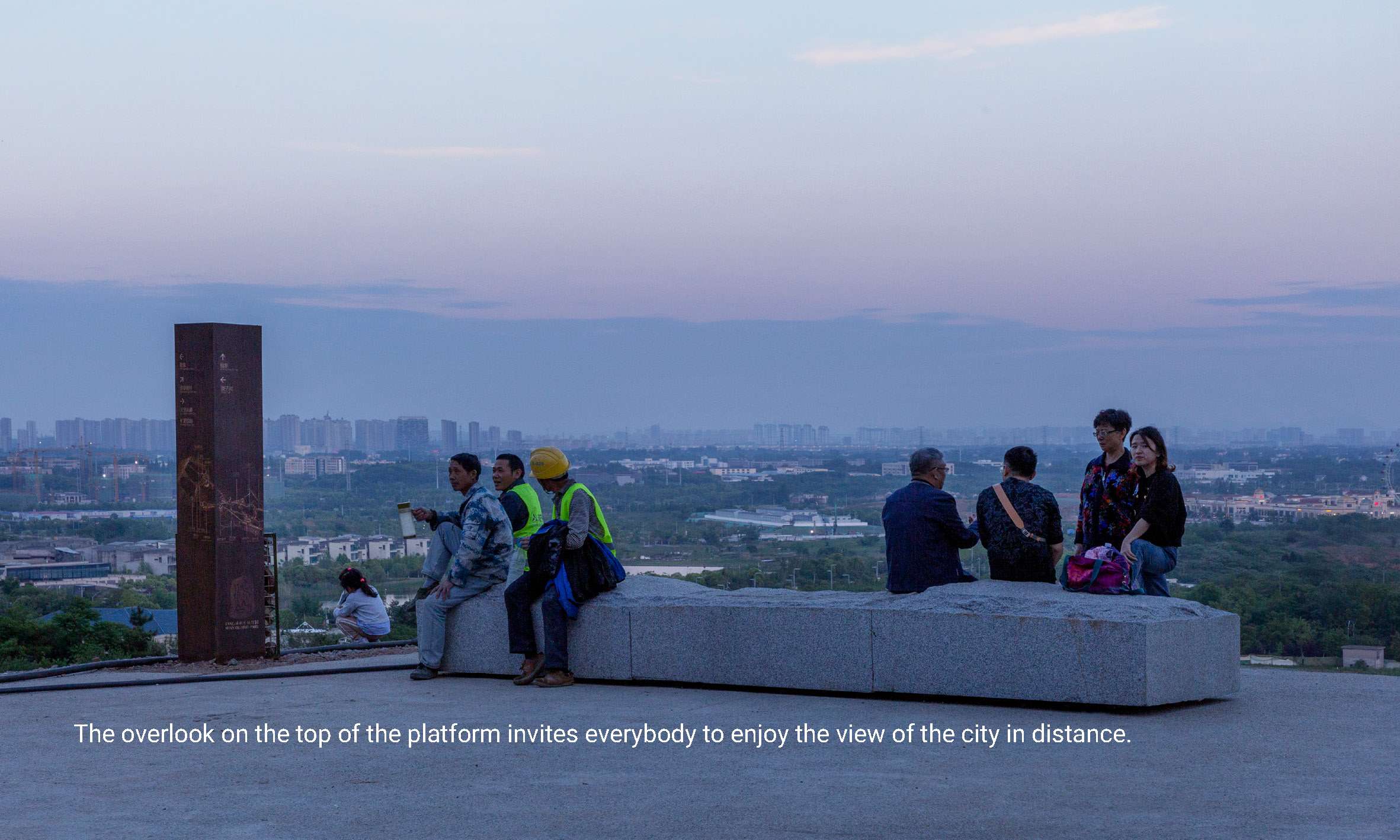

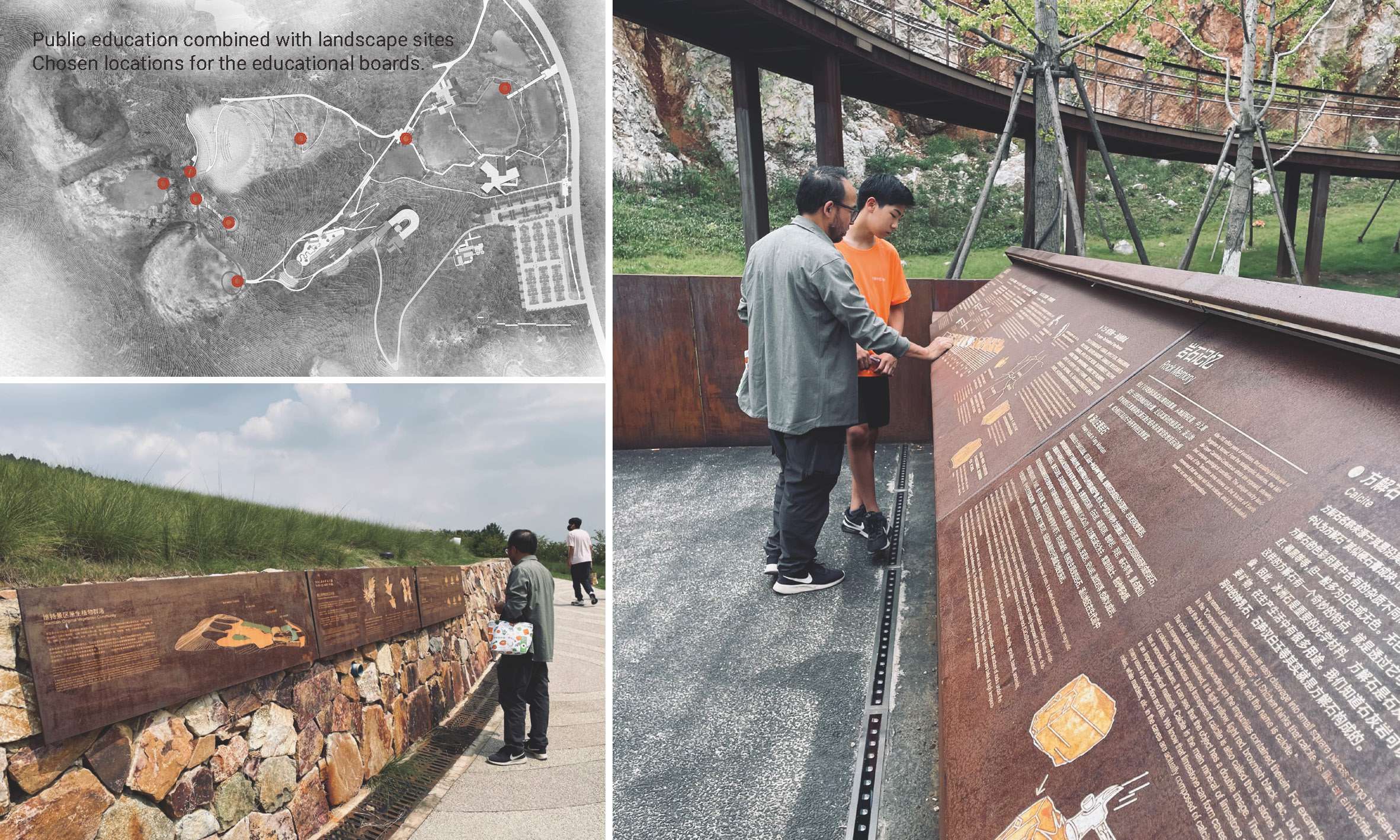

- Incorporating the given terrain & functional regeneration. Comparing to the approach to fully repair the rock walls of the quarry craters, we took an alternative to repair the rock walls selectively and strategically. After the detailed evaluation of the rock walls, we sorted the walls into two categories - to repair and to preserve. The preserved rock walls became education walls that offer the first hand and close up experience of the erosion of the mountain caused by mining. After careful evaluation of three key factors of the craters – safety, ecological condition and terrain, we selected two craters to introduce human activities throughout the craters. As the decade of heavy mining activities had broken down the mountain and made the then cohesive ecosystem fragmental, we re-organized the vicinity and introduced a series of experience-based activities based on what the individual area could offer.

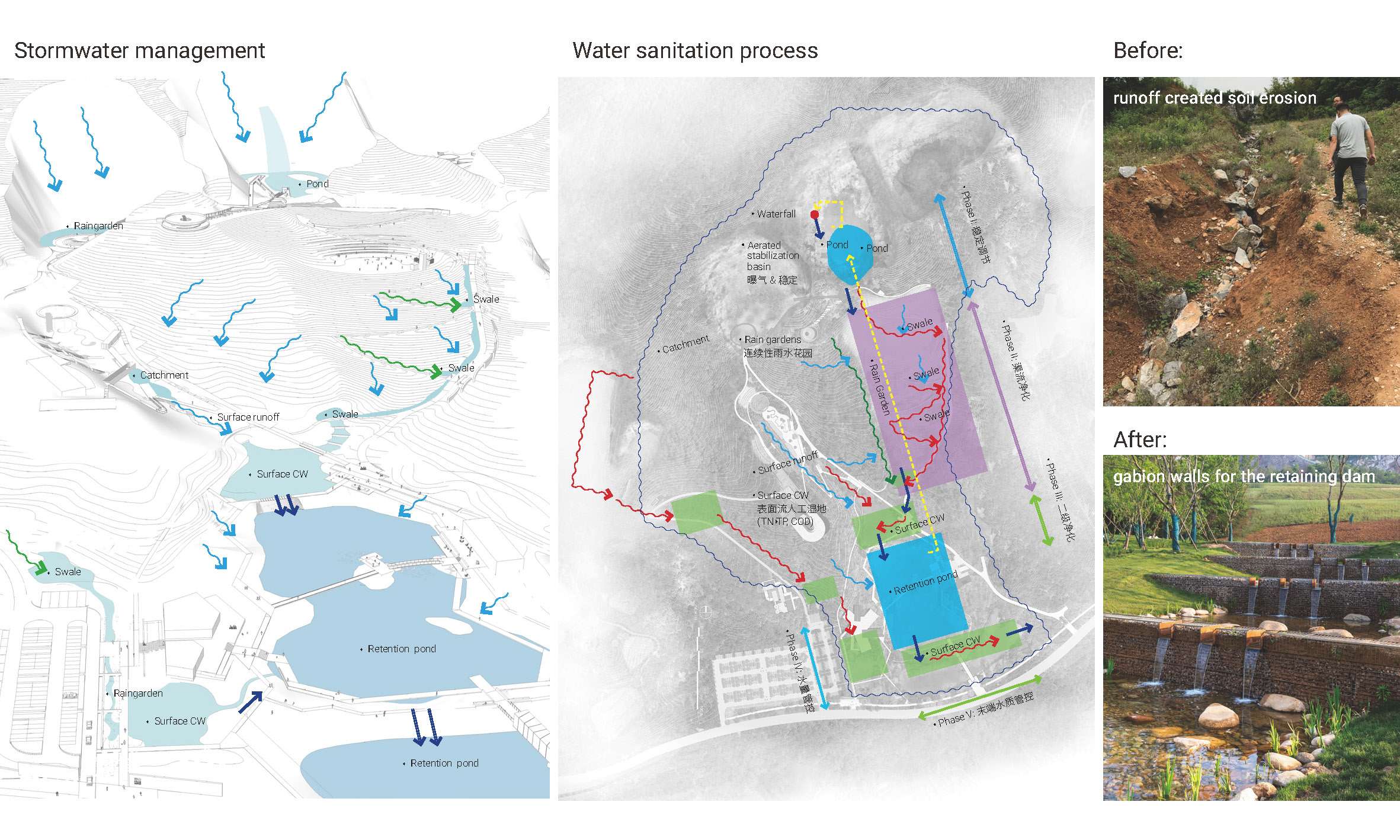

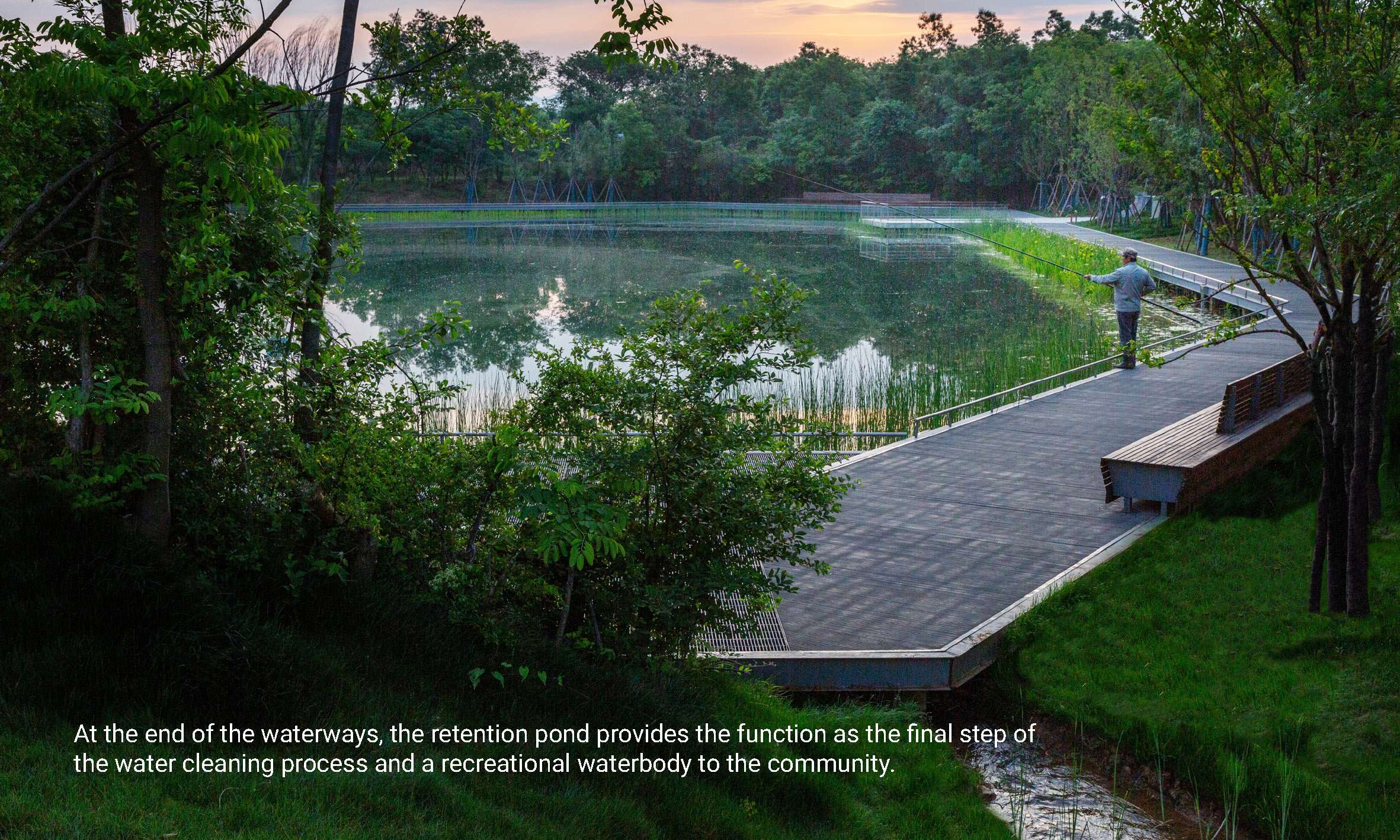

- Runoff control & Water system management: A system was designed to manage the runoffs in the field. First, the run-off water from the high points in the mountain will be retained in the reservoirs at the bottom of the crater; as the water in the reservoirs moves downstream, the water runs through bioretention swale. The bioretention swale helps to reduce the run-off, filter the pollutants, and control the passage of the storm water wash over. The bio-swale is designed as a system with multiple nods, which enables the detailed management of the water and increases the efficiency of filtration. At the end of the waterways, we designed a natural bottom wetland/pond. All water will be gathered in the pond for the final cleaning process. After 3 years performing, the quality of the water at the bottom reservoir could reach to the quality of ground water Category 3.

- Restoration rock walls & reuse of the fertilized soil. The task included 1) to restore the bare rock walls; 2) to stabilize the rock walls in danger of falling and collapsing; 3) to preserve selected rock walls as the illustration. The sapropel from the original fishing pond was transferred to the large scaled damaged field (used to be the quarry dumping site) on the mountainside as fertilizer. 150,000 cubic meters of sapropel was used to restore 120,000 cubic meters flower bed for meadows.

- Biodiversity species composition & controlled human intervention. One of the main goals of the project is to increase and sustain the biodiversity and to restore the ecosystem on the site. In order to achieve the goal, the project employed three strategies – 1) to engage with spontaneous plants by limited human-directed planting design; 2) to control the invasive species by restore the native species; and 3) to encourage vernacular biodynamic habitat for the endangered species.

- Strategically selection of the introduced materials: Locality, Low maintenance and Low cost (3L) are the principles of the design based upon. For example, the designed specified the rocks for the construction were the reused crushed stone found on site with little to no processing requirement needed.

- Playground for recreation & education: A playground was introduced by using the exiting dumping site alongside the quarry cater, with design language based upon quarry industry transportation mechanism, structure, and material. The narratives of the mining process were transformed into slides, swings, trampoline, etc. with Corten Steel beam, frame, and tower. It effectively recalls the history and turn out to be a part of public education in the park.

Sustainable operation and maintenance

For the past 5 years, the natural ecological condition in the quarry has improved significantly. The rock fractures in the caters start to be recovered by spontaneous plants, the soil erosion has been controlled, and the water quality level has been upgraded. The indigenous ecology has been preserved and enhanced, at the same time offers an experience-based educational environment to the locals and tourists. Based on the statistic at the end of 2021, the site has successfully transformed an abandoned quarry to a dynamic and sustainable public park that accommodates one million visitors per year. In addition, the Tangshan Quarry Park official management balance their maintenance for the heavily used public areas with the income of small retails and the playground for the financial support. It has satisfied the purposes of to restore the ecology, sustain the operation financially and socially, and set an example for the future sustainable development of such public realm in the region.

Design Team: Qing ZHANG, Min XU, Yifan CHEN, Shuai YUAN, Yupeng YANG, Xin LIU, Shaohao BIAN

Installation Design: Z+T Art Studio

Playground engineer: Hongchao LIU, Jialin ZHENG, Yanjie FAN, Chuan SUN

Photography: Hai ZHANG, Bing LU

Ecologist: Mo WANG

Geological hazard assessment: Jiangsu Huadong Construction Foundation Engineering Co., Ltd.

Site environmental assessment: Nanjing Guohuan Science And Technology Co., Ltd

Architecture design: Urban Planning&Design Institute of S.E.U

Tourism planning: Nanjing Tongdao Architectural Design Co., Ltd